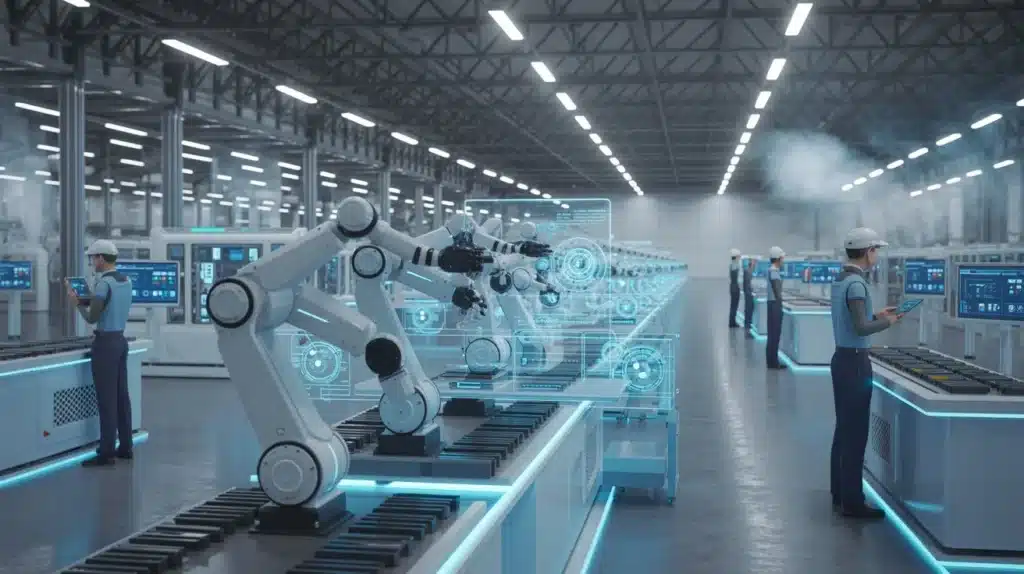

Walk into a modern factory today and you might not recognize it as manufacturing at all.

Robots work alongside humans, not instead of them. Sensors monitor every machine, predicting failures before they happen. Digital twins, virtual replicas of entire production lines, test new processes without stopping a single assembly line. AI systems optimize everything from energy consumption to supply chains in real time.

This isn’t science fiction. It’s happening right now at facilities run by TSMC in Phoenix, Samsung in South Korea, Toyota in Kentucky, and thousands of other manufacturers worldwide.

The numbers tell a compelling story: 92% of manufacturers believe smart manufacturing will be the main driver for competitiveness over the next three years, a six percentage point increase from 2019. Meanwhile, $1.2 trillion in investments toward building out U.S. production capacity was announced in 2025, led by electronics providers, pharmaceutical companies and semiconductor manufacturers.

But here’s what makes this moment different from previous industrial revolutions: Instead of merely automating tasks, AI is reshaping industry processes. It’s fundamentally changing what manufacturing means, creating smarter factories, new types of jobs, and a workforce where humans and machines collaborate in ways we’re only beginning to understand.

The Smart Factory Revolution: What’s Actually Happening on Factory Floors

Defining Smart Manufacturing

A smart factory isn’t just a traditional plant with some robots added. Smart manufacturing uses a combination of connected technologies, real-time data analytics and AI to create flexible, efficient and highly automated manufacturing systems.

Think of it as Industry 4.0 meeting real-world production challenges. Every machine, sensor, and worker is connected through a digital nervous system that collects data, makes decisions, and continuously optimizes operations.

Real Companies, Real Results

TSMC (Phoenix, Arizona)

TSMC is using Omniverse to accelerate fab design and construction, as well as the NVIDIA Isaac platform for the development of robotics for specific operations at its Phoenix, Arizona, facility to significantly enhance manufacturing productivity. The world’s leading semiconductor manufacturer is bringing cutting edge AI driven manufacturing to American soil.

Samsung Electronics

Samsung’s semiconductor AI factory will be a centerpiece of the company’s digital transformation, integrating accelerated computing directly into full fledged advanced chip manufacturing. Powered by more than 50,000 NVIDIA GPUs, the real-time digital twin of the Samsung fab will enable operational planning, anomaly detection and logistics optimization, a significant step toward a fully autonomous fab.

Toyota (Georgetown, Kentucky)

Toyota is using idealworks’ iw.sim technology, which integrates capabilities from the Mega Omniverse Blueprint, to create digital twins of its Georgetown, Kentucky, facility and explore complex automation scenarios. One of the world’s most efficient manufacturers is using AI to get even better.

Siemens (Amberg, Germany)

Siemens’ Amberg Electronics Plant in Germany uses cutting-edge technologies like automation, robotics, and data analytics to streamline production processes and boost efficiency. By leveraging this technology, Siemens has been able to: automate 75% of its supply chain with robots, achieve a 99.9% quality standard, and produce over 1,000 product variations daily.

Bosch

Bosch’s smart factory incorporates digital twins to simulate and improve manufacturing processes, as well as robotics to automate repetitive tasks. This factory uses the Nexeed software suite to connect over 60,000 sensors, resulting in a 25% increase in production efficiency. Moreover, its comprehensive automation platform has demonstrated a 30-50% reduction in component and engineering costs.

These aren’t pilot programs or experimental projects. These are production facilities manufacturing billions of dollars worth of products every year.

The Technologies Powering Smart Factories

1. Artificial Intelligence and Machine Learning

AI, automation and machine learning are becoming the norm, with data playing an even greater role in the manufacturing process. But what does that actually mean on the factory floor?

Predictive Maintenance: Instead of waiting for machines to break down, AI analyzes sensor data to predict failures before they happen. AI driven analytics can accurately predict machine failures, preventing costly downtime and minimizing production disruptions. Advanced machine learning models analyze sensor data in real time, identifying subtle anomalies before they turn into failures.

Quality Control: AI’s most beneficial capability within factories is computer vision, which enables real-time defect detection. Instead of relying solely on human inspectors, AI powered systems scan products in milliseconds, flagging even the smallest imperfections before they leave the production line.

Foxconn, a leading electronics producer, has integrated AI and computer vision into its production processes to rapidly and accurately detect defects in electronic components through image and video analysis.

Adaptive Production: Unlike traditional robots that follow pre-programmed instructions, AI powered cobots adjust to variations in assembly processes, handle multiple vehicle models, and even identify quality issues on their own.

2. Digital Twins

Around 75% of companies in advanced industries are harnessing digital twin technology. Digital twins are highly beneficial in creating virtual replicas of physical assets and processes, whether that be a factory floor layout or individual products and components.

Virtual replicas of physical systems, digital twins allow manufacturers to test new processes, identify bottlenecks, and fine-tune operations before a single wrench is turned.

Imagine being able to redesign your entire production line, test it thoroughly, identify problems, and optimize it, all without stopping actual production for a single minute. That’s the power of digital twins.

3. Collaborative Robots (Cobots)

Traditional industrial robots operated in cages, isolated from human workers for safety. Cobots are different.

Collaborative robots (cobots) differ from traditional industrial robots that require protective cages for safety. Cobots are designed to work alongside humans, with built-in safety features such as force limiting sensors and real-time responsiveness that allow them to operate safely in shared workspaces.

Adding just one cobot to a team and replacing a single human worker can increase production output by up to 40%. Cobots are taking the weight off employees, by lifting heavy packages; they are reducing ergonomic risks and accelerating processing by 10%.

Hanwha Ocean is deploying cobots at its Geoje shipyard to assist with high risk tasks like welding and painting, improving worker safety and production consistency.

4. Industrial Internet of Things (IIoT)

By connecting machinery, sensors, and devices, IIoT enables real-time data collection and analysis, offering insights into every aspect of production.

Every machine becomes a data source. Every process becomes measurable. Every inefficiency becomes visible.

The result? Reduced operational costs through predictive maintenance, AI driven energy management, and automation that reduces waste and lowers overall manufacturing expenses. Higher quality and lower defect rates through AI powered defect detection systems that enhance product consistency and reduce recalls.

5. Edge Computing

Edge AI empowers manufacturing facilities by distributing computing power directly onto the production floor, enabling sensors embedded in machines to analyze data in real time. Unlike traditional AI systems that rely on centralized cloud-based processing, edge AI processes data locally on the device itself or within a localized network.

Why does this matter? Speed. When AI processes data right where it’s generated, on the factory floor, decisions happen in milliseconds instead of seconds. That’s the difference between catching a defect and shipping it to customers.

The Productivity Transformation: What the Data Actually Shows

Labor Productivity Gains

Using study data and forecasting models, labor productivity will likely grow at a compound annual rate of 2.3 percent during 2025–2030, closer to the level last seen in the 1990s. This represents triple the labor productivity growth rate during the next decade (2019–2030) compared to last decade (2007–2018).

To put this in perspective: manufacturing productivity had essentially flatlined for two decades. Now it’s accelerating again.

A Deloitte study found that companies that took smart factory initiatives saw a 12% increase in productivity, an 11% increase in capacity utilization and a 10% increase in output over three years. And those are figures from 2019. As we break down more technological barriers in 2025, the capabilities only increase.

What Manufacturers Are Actually Seeking

49% of respondents reported operational benefits as the primary value sought with smart manufacturing, while 44% noted financial benefits as the second most-sought value.

The top operational benefits include:

- Reduced downtime through predictive maintenance

- Improved quality control and fewer defects

- Greater flexibility to handle custom orders

- Real-time visibility into production processes

- Better supply chain coordination

The financial benefits are equally compelling:

- Reduced operational costs, higher quality and lower defect rates, supply chain agility, sustainability and ESG compliance, and greater customization capability

Market Growth

One report suggests that the smart factory market will grow from 100.6 billion USD to 164 billion USD between 2024 and 2029, primarily driven by a pursuit of operational excellence.

This isn’t speculative investment money chasing hype. These are manufacturing companies spending real capital to build competitive advantages.

The Worker Question: What’s Actually Happening to Manufacturing Jobs

This is where the conversation gets complicated, and where most coverage gets it wrong.

The Displacement Numbers

The data on job losses is real and significant:

According to an MIT and Boston University report, AI will replace as many as two million manufacturing workers by 2025.

Oxford Economics predicts that as many as 20 million manufacturing jobs could be replaced globally by 2030. Manufacturing is forecasted to lose 2 million jobs by 2025 due to the integration of robotics and AI.

The U.S. manufacturing industry lost 78,000 jobs over the past year with 12,000 cuts in August alone. Manufacturing jobs have been declining since February 2023, now reaching the lowest level since the onset of the COVID-19 pandemic.

The Complexity Beneath the Headlines

But here’s what those numbers don’t capture:

Manufacturing companies have been facing a labor shortage for years. Nearly 2 million jobs, half of all new positions created, could be unfilled by the end of the decade, according to data from Deloitte and The Manufacturing Institute.

Think about that paradox: Manufacturing is both losing jobs to automation AND struggling to find enough workers.

Modern manufacturing increasingly requires workers who can oversee AI systems, interpret data outputs, and handle exceptions that automated systems cannot manage. The transformation emphasizes human AI collaboration. Workers use AI for predictive maintenance, quality control, and supply chain optimization. Manufacturing jobs evolve toward higher-skill positions that combine technical knowledge with digital literacy.

What’s Actually Changing

Many experts point to reskilling as a solution, saying workers’ responsibilities could change rather than be completely eliminated. “Factories will keep getting smarter and more automated, but people will not disappear from the equation. The larger shift is that there are not just fewer jobs, but different jobs”.

Consider what’s happening at the companies we mentioned earlier:

- TSMC isn’t just replacing workers with robots. It’s training workers to operate, maintain, and optimize those robotic systems.

- Samsung’s 50,000-GPU AI factory still employs thousands of people, but they’re doing fundamentally different work than assembly-line workers did 20 years ago.

- Toyota’s digital twin facility in Kentucky still has humans making critical decisions based on AI insights.

The workers who thrive in these environments aren’t traditional assembly-line workers or pure engineers. They’re hybrids, people who understand both the physical manufacturing process and the digital systems that optimize it.

The Skills That Matter Now

Technology alone cannot address the most significant hurdles that manufacturers face amid the current industrial workforce gap. Not only will we see a growing emphasis on collaborative technologies in 2025, such as collaborative robots that augment workforce gaps, but we’ll also see a growing emphasis on workforce development. We’ll see more action around engaging the next generation of manufacturers earlier in their lives. But for more immediate impact, we’ll see more manufacturers looking to upskill their workers to give them the training needed to work alongside advanced technologies.

59% of workers will require upskilling or reskilling by 2030. 39% of key job skills in the U.S. are expected to change by 2030.

The New Manufacturing Workforce: Real Roles, Real People

Let’s get specific about what jobs actually exist in AI driven manufacturing:

Technical Roles

MLOps Engineers: Manage the lifecycle of AI models used in predictive maintenance and quality control systems.

Computer Vision Engineers: Design and optimize the AI systems that inspect products for defects at superhuman speed and accuracy.

Robotics Technicians: Maintain, program, and troubleshoot the cobots and autonomous systems on the factory floor.

Digital Twin Architects: Create and maintain virtual replicas of production systems, running simulations to optimize processes.

Edge Computing Specialists: Deploy and manage the AI systems that process data directly on the factory floor for real-time decisions.

Hybrid Roles

Manufacturing Data Analysts: Bridge the gap between production floor realities and AI insights, translating machine learning outputs into actionable operational decisions.

Human-Robot Collaboration Coordinators: Design workflows where humans and machines work together optimally, ensuring safety and efficiency.

Process Optimization Specialists: Use AI tools and traditional manufacturing knowledge to continuously improve production processes.

Leadership Roles

AI Manufacturing Directors: Oversee the deployment and management of AI systems across entire facilities.

Smart Factory Architects: Design the overall technology infrastructure that connects machines, data, and workers.

Workforce Development Managers: Lead reskilling and upskilling initiatives to prepare workers for AI augmented roles.

The pattern is clear: These aren’t jobs where AI replaces humans. They’re jobs where humans work with AI to achieve things neither could do alone.

Geographic Shifts: Manufacturing’s Return to Advanced Economies

Something unexpected is happening: Advanced manufacturing is coming back to high-wage countries.

In 2025, reshoring and nearshoring are accelerating as companies work to strengthen supply chain resilience and reduce reliance on distant suppliers. Beyond reducing supply chain disruptions, nearshoring offers a range of benefits. By keeping production closer to demand, manufacturers can respond more quickly to market shifts, improving flexibility and operational agility.

Why now? Because AI and automation are changing the economics:

- Labor costs matter less when robots do the repetitive work

- AI reduces the advantage of cheap labor by minimizing human involvement in routine tasks

- Supply chain resilience matters more after COVID-19 exposed vulnerabilities

- Advanced manufacturing requires skilled workers who can operate sophisticated systems

Leading companies like TSMC, Wistron, and others are implementing advanced manufacturing facilities in the United States, bringing high-tech production back to American soil.

This isn’t your grandfather’s manufacturing coming back. It’s high-tech, AI driven production that creates different kinds of jobs requiring different kinds of skills.

The Challenges: What’s Actually Hard About This Transition

Let’s be honest about the obstacles:

1. Implementation Costs

Building a highly automated, interconnected facility may have its benefits, but it also comes at a significant cost. Whether it’s the capital required to implement technologies or the hidden costs required to train employees, manufacturers may struggle to wrap their heads around the finances of it all. However, those who adopt a long-term view will see that the enhanced efficiency and productivity make up for the high initial investment.

2. Skills Gap

As technology advances, the workforce must keep up, acquiring the skills that allow them to understand and operate such advanced processes. Unfortunately, many factories are currently facing a glaring skill gap, especially considering how quickly new technologies are adopted.

3. Integration Complexity

While information technology and operational technology have traditionally occupied distinct domains, their integration has been essential. Getting IT systems to talk to factory floor equipment isn’t trivial. Many manufacturers struggle with legacy systems that don’t play nice with modern AI platforms.

4. Cybersecurity

When every machine is connected and every process is digitized, security becomes paramount. A cyberattack on a smart factory could shut down production entirely or compromise proprietary manufacturing processes.

5. Change Management

Technology is only part of the challenge. Getting workers, managers, and executives to embrace new ways of working often proves harder than implementing the technology itself.

Sustainability: The Unexpected Benefit

Sustainability is no longer a secondary consideration for manufacturers; it has become a core business objective. In 2025, smart manufacturing technologies will increasingly focus on reducing energy consumption, minimizing waste, and lowering carbon footprints.

AI doesn’t just make factories more efficient, it makes them greener:

Energy Optimization: AI driven smart factories can also optimize energy consumption by automatically adjusting power use based on real-time needs, leading to more sustainable and cost-effective operations.

Waste Reduction: AI algorithms optimize material usage, leading to less waste. IoT sensors help factories monitor and reduce energy consumption.

Predictive Maintenance: Keeping machines running optimally reduces energy waste and extends equipment life, reducing the environmental impact of manufacturing new machinery.

ABB’s Ability™ and Schneider Electric’s EcoStruxure™ are comprehensive solutions for optimizing industrial operations. They leverage AI and data analytics to enhance energy efficiency, reduce waste, and improve resource utilization.

This is a rare win-win: Better for business and better for the planet.

What’s Next: The Road to Autonomous Factories

The Four Levels of Factory Automation

In level three, the integration of AI and machine learning advances to a point where operators can make adjustments in real time. These advanced algorithms allow factory workers to study historical data to identify the most efficient production schedules, diagnose equipment failures for engineers or even adapt to changing demands. By the last stage, automation professionals have given the factory such a high level of autonomy that it is able to act on its own recommendations. This could include adjusting parameters, scheduling maintenance or conducting quality checks.

We’re currently in the transition between levels two and three. Most smart factories can monitor and analyze, and increasingly they can recommend actions. The next frontier is full autonomy, factories that can operate and optimize themselves with minimal human intervention.

Emerging Technologies to Watch

Agentic AI: Moving beyond reactive AI to systems that can plan, execute multi-step tasks, and collaborate with other AI agents to solve complex manufacturing challenges.

Physical AI: Companies are using applications from independent software vendors and Omniverse libraries to build robotic factories that can power this wave of industrialization, using physical AI and simulation to accelerate manufacturing.

Humanoid Robots: Samsung is charting the future of intelligent robotics across manufacturing automation and humanoid robot applications using NVIDIA robotics technologies. Combined, these technologies enable the deployment of robots that can understand and interact with the physical world in real time.

5G and Beyond: Ultra-low latency communications enabling even faster machine-to-machine coordination.

Practical Guidance: What Different Stakeholders Should Do

For Current Manufacturing Workers

Don’t panic, but don’t wait:

- Start learning about the technologies in your facility. Ask questions. Volunteer for training programs. Show interest in how the new systems work.

- Focus on hybrid skills. The best safeguard for both workers and employers is steady investment in skills, so people are prepared to move into the roles that the market continues to demand.

- Emphasize what you know that AI doesn’t. Your deep understanding of the actual production process, your ability to spot problems by sound or sight, your knowledge of how to work around issues, these remain valuable.

- Consider certifications. Community colleges and manufacturers increasingly offer training in industrial AI, robotics operation, and data analytics.

For Manufacturing Company Leaders

- Think transformation, not just automation. 85% of respondents believe their smart manufacturing initiatives will transform how products are made, improve agility, and attract new manufacturing talent.

- Invest in your current workforce. RBC and other leading companies are asking workers across functions to become familiar with using AI tools. This is cheaper and more effective than replacing your entire workforce.

- Start with high-impact use cases. Don’t try to transform everything at once. Identify specific pain points where AI can deliver clear ROI quickly.

- Build dedicated transformation teams. Manufacturers are emphasizing workforce upskilling and building dedicated internal teams to drive change and transformation.

For Job Seekers Entering Manufacturing

The opportunity is real:

Manufacturing isn’t your parents’ industry anymore. Modern factories are high tech environments that combine engineering, data science, and traditional manufacturing expertise.

Key skills to develop:

- Basic programming (Python, especially)

- Data analysis and visualization

- Understanding of AI/ML fundamentals

- Domain knowledge in specific manufacturing processes

- Problem-solving and critical thinking

- Communication skills to bridge technical and operational teams

Entry paths:

- Technical degrees in mechatronics, industrial engineering, or data science

- Apprenticeships at smart factories

- Community college programs in industrial automation

- Veterans with technical military backgrounds

- Career switchers from IT into industrial applications

For Educators and Policy Makers

We’ll see more action around engaging the next generation of manufacturers earlier in their lives.

Manufacturing needs to rebrand itself. Young people don’t dream of working in factories because they picture 1970s assembly lines. They need to see modern smart factories, clean, high-tech environments where robots and humans collaborate, where data drives decisions, and where innovation happens daily.

The skills gap is real and growing. Educational institutions need to partner with manufacturers to design curricula that prepare students for the actual jobs that exist and will exist, not the jobs that existed 30 years ago.

The Bottom Line: Manufacturing’s AI Future Isn’t Binary

The common narrative presents a false choice: either AI replaces all workers, or it doesn’t affect jobs at all. Reality is messier and more interesting.

Artificial Intelligence is transforming manufacturing in ways that are simultaneously creating displacement and opportunity. While 85 million jobs are expected to be replaced worldwide by 2025, 97 million new roles will simultaneously emerge, representing a net positive job creation of 12 million positions globally.

But these numbers mask the human reality: The new jobs aren’t always in the same locations as the displaced ones. They require different skills. They’re not one-for-one replacements.

What we know for certain:

- Smart factories are the competitive future of manufacturing. 92% of manufacturers believe smart manufacturing will be the main driver for competitiveness over the next three years. Companies that don’t transform will lose to companies that do.

- Productivity gains are real and significant. Labor productivity will likely grow at a compound annual rate of 2.3 percent during 2025–2030, representing triple the labor productivity growth rate of the previous decade.

- Jobs are changing, not just disappearing. Manufacturing jobs evolve toward higher-skill positions that combine technical knowledge with digital literacy.

- Adaptation is mandatory. Workers, companies, and regions that embrace change and invest in skills will thrive. Those that resist will struggle.

- Human expertise remains critical. Even in the most automated factories, humans make key decisions, solve unexpected problems, and provide the judgment that AI still lacks.

The factories of 2030 won’t be empty of humans. But the humans working there will be doing fundamentally different work than their predecessors. They’ll be overseeing AI systems, interpreting data, solving complex problems, and continuously learning new skills.

The question isn’t whether AI will transform manufacturing. It already has. The question is whether workers, companies, and communities will adapt quickly enough to capture the benefits while managing the disruptions.

The manufacturing industry is being rebuilt right now, factory by factory, technology by technology. The winners will be those who see this not as a threat to be feared, but as an opportunity to be seized.

Quick Action Steps

For Workers:

- Ask about training programs at your facility

- Take online courses in data analytics or Python

- Volunteer to work with new technologies

- Join industry associations focused on smart manufacturing

For Companies:

- Conduct an AI readiness assessment

- Identify one high-value use case for a pilot project

- Create a workforce development strategy

- Partner with technology providers and educational institutions

For Educators:

- Reach out to local manufacturers to understand skills needs

- Develop programs combining manufacturing knowledge with AI literacy

- Create pathways for mid-career workers to reskill

- Showcase modern manufacturing to students as a career option

The smart factory revolution is here. The only question is whether you’ll be part of shaping it, or swept along by it.